Automated Hand Soldering for Manufacturing

A major factor slowing down electronics production time across industries is the need for complex and intricate hand soldering.

This work requires highly skilled labor that is subject to turnover and scarcity due to the competitive nature of the trillion-dollar industry. When it comes to your business, the lack of skilled labor can delay production times and hurt your ability to scale with the momentum of the market.

Predictable Costs Protect Profit Margins

Predictable Costs Protect Profit Margins

The hiring and turnover of skilled labor can cause a chain reaction through your production process that causes costly delays and destroys your margins.

The SB-1 is currently working in over half a dozen industries to help businesses of all kinds protect their profit margins and grow at a consistent, steady pace.

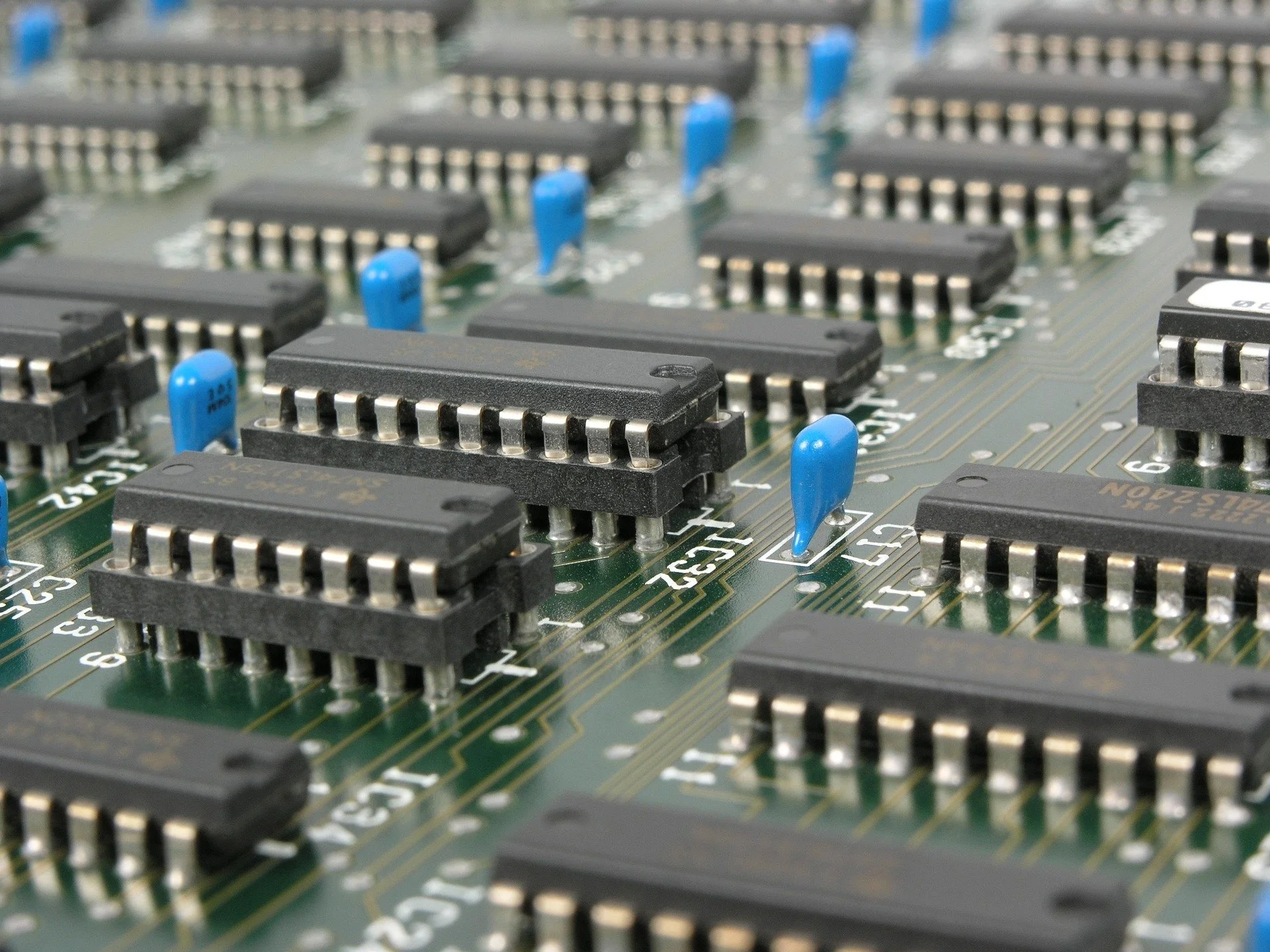

Consumer Electronics

Traditionally, producing consumer electronics at scale requires a large, skilled labor force for hand soldering tasks.

The SB-1 is capable of handling high-volume production workloads and recreating human hand soldering processes indistinguishable from its human labor counterparts.

Automotive Electronics

A vehicle's electronic capabilities, from touchscreens to wifi and Bluetooth connectivity, have become nearly as important as its engine size or miles per gallon to consumers.

As cars continue to integrate advanced computer electronics into the majority of new models, the demand for hand-soldering will only continue to increase, driving up labor costs alongside scarcity.

5G Infrastructure

As more and more of the cellular grid upgrades to 5G, the demand for industrial grade hand soldering grows. High-quality hand soldering is often a key component of the lossless signal that sets 5G apart.

The SB-1 is built to answer this rising demand. It’s capable of being programmed for the unique challenges of hand soldering 5G infrastructure.

Medical Devices

Revenue from medical device sales is estimated to reach nearly 720 billion dollars by 2030. As traditional devices like pacemakers and insulin pumps continue to evolve, so does the growing number of medical and fitness tech wearables like smart watches, glasses, and even AI companionship wearables.

With so much demand for high volume, low-failure-rate hand soldering, automating the hand soldering for your production process helps to future-proof your business and increase your profit over the long term.

Industrial Electronics

Hand soldering for industrial electronics requires extensive knowledge of a variety of different configurations and layouts. The low-volume, but complex nature of the work typically leads to an over-reliance on human labor.

Automating these hand soldering tasks helps to protect your production process from unnecessary vulnerabilities and increasing costs.

The SB-1 Soldering Robot

The SB-1 is being used across over a dozen industries and continues to help companies lower their cycle time and reduce reliance on human labor.

Using a six-axis Cobot and a cutting-edge AI vision system, the SB-1 can replicate complex human soldering processes and monitor them in real time for enhanced quality control.

Connect with Us Today

Interested in seeing how the SB-1 can stabilize your hand soldering process?

Use the form below or email us at sales@arbot.ai.