The SB-1:

The Only Fully Automated Soldering Robot

More Consistency, More Profit

The SB-1 is Adaptive Robotics’ answer to all of your hand soldering needs. Our robot is built to replicate many of the skills previously reserved for hand soldering in electronics manufacturing.

Shifting production from human labor to robotics allows you to reduce your cycle time and avoid the unpredictable downtime factors of human labor.

Skilled Labor Shortage Solved

We built SB-1 to be your company’s next best hire. Finding and replacing skilled labor is costly, time-consuming, and can lead to further production delays.

The SB-1 eliminates this financial stress and unpredictability from your business and protects you from the production bottlenecks caused by labor turnover that jeopardize contracts and business relationships.

Our automated soldering machine is made to fit in with your already existing equipment ecosystem, and will be custom-tailored to meet your business’s hand soldering needs. This includes the end-to-end automation programming that can replicate any of your current soldering processes. Our expert technicians will arrive on-site for a comprehensive installation, including training sessions for your staff members to ensure fast integration and safe operation of the machine.

Made for Your Hand Soldering Needs

Programming Your SB-1

Check out our demo below, which shows off how the SB-1 can be programmed step by step to handle your most complex hand soldering production needs. You can see how the SB-1’s robotic arm documents its entire field of view and responds in real time to new steps being added to the production process.

Parts and Labor Warranty

The SB-1 was designed and manufactured in the USA by soldering professionals. It’s made for the rigors of commercial production, and multiple machines can be programmed for production load management.

For additional peace of mind, all SB-1 automated soldering robots include a 1-year warranty for any required parts and labor.

We also provide ongoing technical support throughout the warranty period, and we’ll continue to be here as your partner to ensure the SB-1 is the most consistent machine in your assembly line.

The New Generation of Automated Hand Soldering

The New Generation of Automated Hand Soldering

As a team of hand soldering professionals, we knew firsthand the inefficiencies and limitations of current automated hand-soldering machines. So we set out to make the first truly end-to-end automated soldering robot, and the SB-1 was born.

Each SB-1 is purpose-built to make your hand soldering process smarter, faster, more reliable, and ultimately more profitable.

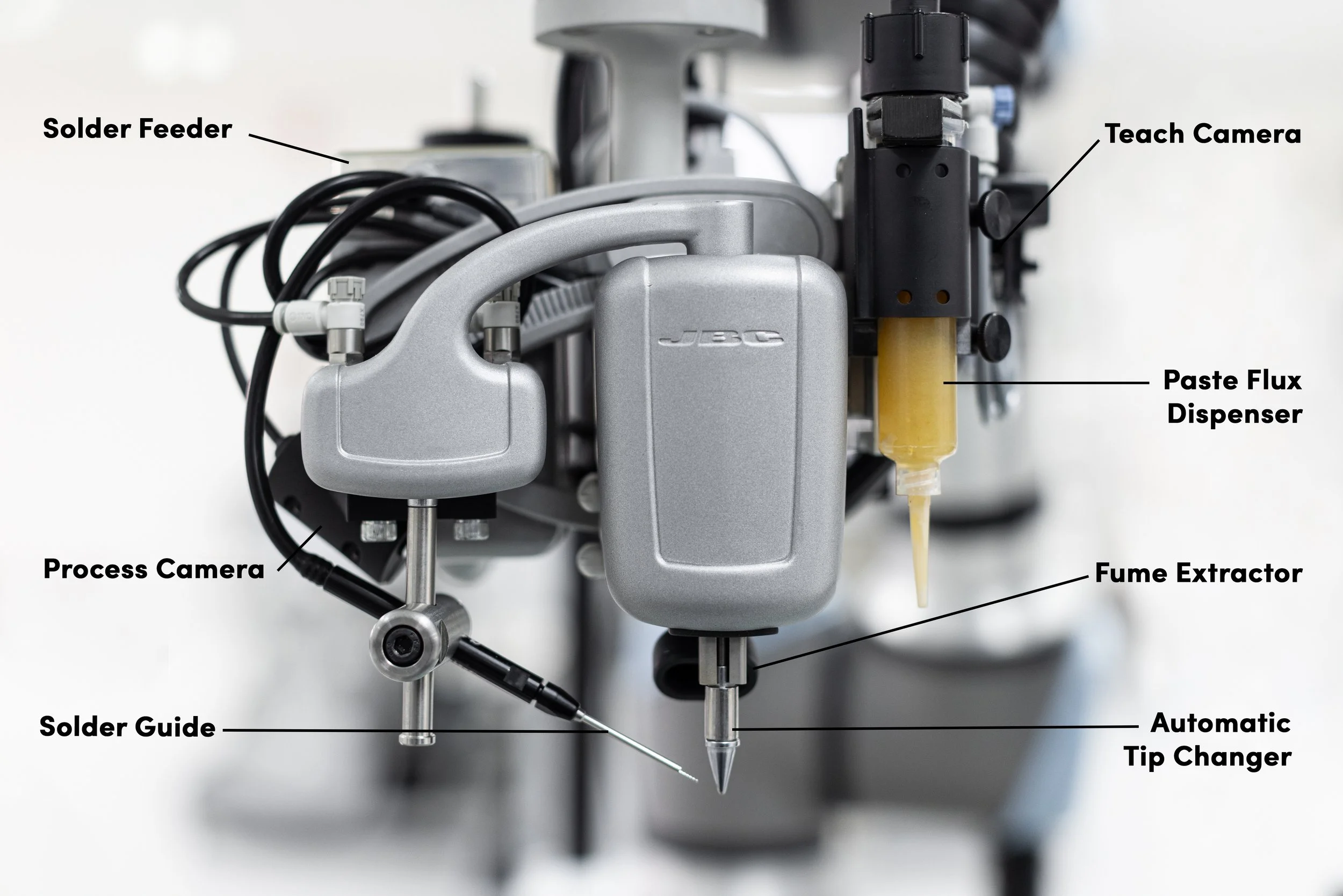

SB-1 Features

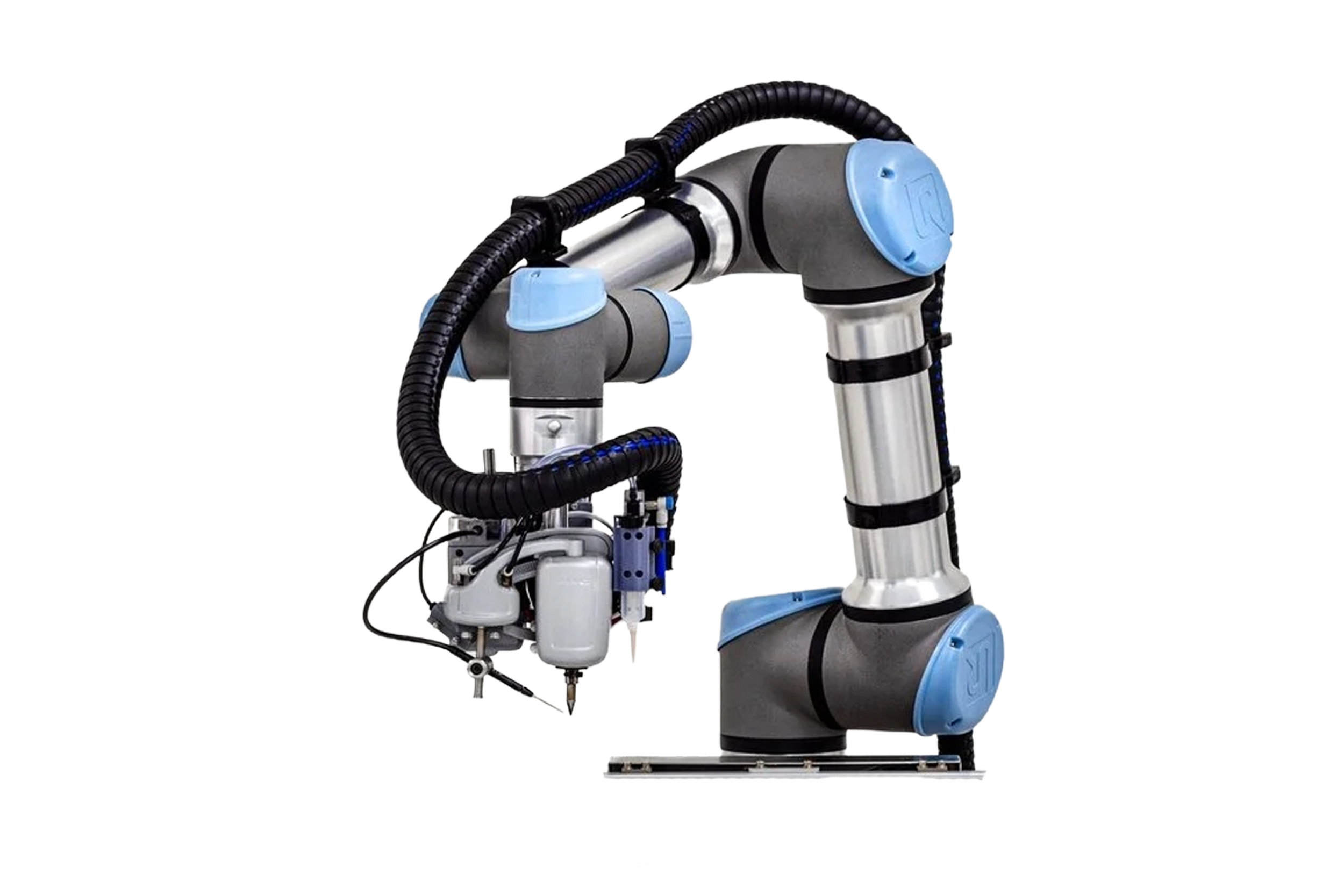

Vision-guided 6-axis automated hand soldering robot

Soldering solution developed by soldering professionals

Custom-developed, easy-to-program software

AI-enabled camera with deep learning capabilities

Scalable software will load balance multiple robots

Traceability for each individual solder joint

Industry-leading JBC soldering head

Real-time process camera with remote view

Dispensing unit for flux or solder paste

Available in conveyor or stationary options

Designed and Manufactured in the USA

SB-1 Specifications

Soldering System

Automatic Soldering Set

Automatic Tip Cleaner

Soldering Tool Control Unit

Solder Feeder with Guide

Collaborative Robot

UR5e 6-axis Cobot

33 inch Reach

5 kg Payload Capacity

Base Frame

Heavy-Duty Frame for Process Stability

Work Area

20 in x 30 in Process Area

User Interface

Egonomic Design

Solder Specification

Ø 0.4 mm

0.015 in through Ø 1.6 mm

0.063 in

AI Vision System

Vision-Guided Position Correction

Barcode Reading

9.1 MP Camera

70 mm Diffused Light Ring

Control PC

Industrial PC with Linux

Intel Ultra 7

32 GB LPDDR5 RAM

1TB NVMe SSD

Dispensing Unit

Precision Flux Dispenser

10cc EFD-Style Syringes

Monitors

Touchscreen Flat-Panel Monitor

Solder Process Camera + Dedicated Monitor with Mount

Fume Extraction

Max Flow Rate: 106 CFM

Facility Requirements

Power: 120V, 15A

Pneumatics: 5 Bar Dry, Clean Compressed Air

Next Steps

If you’re ready to add the SB-1 to your assembly line, get in touch with us here.

Our team will get in touch to schedule a call to begin the assessment process for how the SB-1 automated hand soldering machine can start working for you.